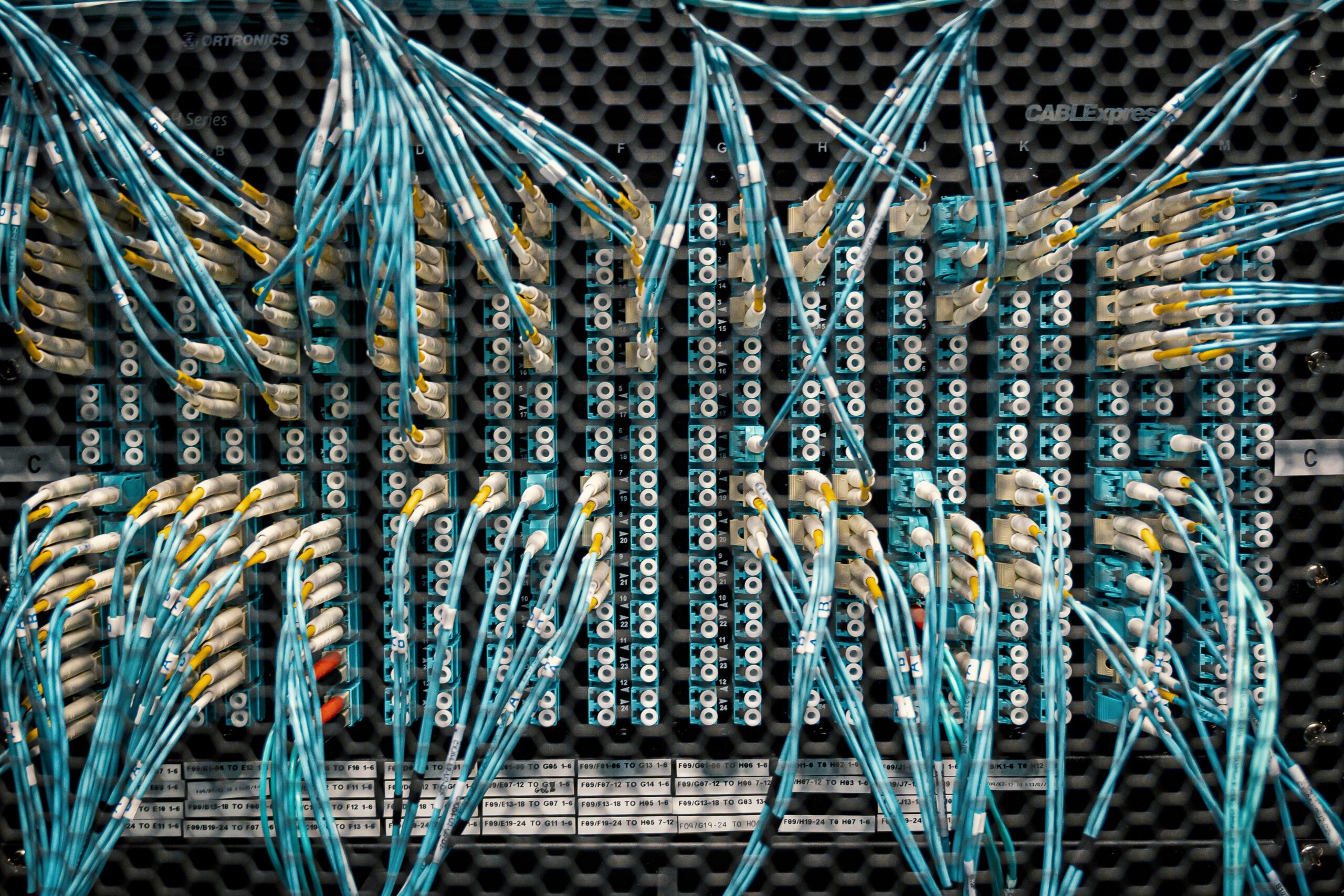

What is Joint Enclosure

The fiber joint enclosure was developed to perform reliably in a number of different settings, including aerial, direct burial, and duct installations. Splicing with them poses no risk to anyone because they are unaffected by both water and earthquakes. Additionally, they are resistant to being cut by sharp objects.

These are available in a wide number of different configurations, some of which have a total of twelve ports, while others include a total of twenty-four ports, forty-eight ports, etc. Both the dimensions of the fiber joint enclosure and the functions that it is designed to carry out can be adapted in order to meet the requirements of a wide variety of applications. There is an Outdoor variation and an Indoor variety of these, and the manner in which they are utilized differs depending on the environment in which the box is kept. For example, an Outdoor variety would be used outside while an Indoor variety would be used indoors.

You will need a container that is resistant to fire, impermeable to water and dust, and constructed of a material that is not readily damaged if you are going to use it for activities that actually take place outside, for instance. In addition to this, the container needs to be made of a material that is strong and cannot be damaged.

It is essential for it to be long-lasting, and it must also be of a size that is appropriate for the task that must be carried out with it. While some joint boxes where are quickly buried close to the floor, others are used overhead, where they are erected above ground. Both types of joint boxes are used for the same purpose. The two distinct types of joint boxes are used for the same thing.

Types of Joint Enclosure

Joint closure connects optical fiber cables. Different wires are fused spliced and stored in the OFC joint closure splice organizer. The enclosure is buried (Main Holes) or hung (Arial cable) from a pole. Armoured or unarmored fiber optic cable has straight or branch joint closure. The joint closure is sturdy and weatherproof. After assembly/heat shrinking, it’s dust- and insect-free.

- Bamboo Type

Optical fiber cable junction closure consists of a molded shell pipe (pipe-shaped with one end closed) with a port cap for cable entry/exits. The end cap holds the sheath clamp, FRP holder, and tray. The cable enters the end cap through ports and is clamped with stealth clamps.

- Features

- Fits 96-fiber cables

- Fits all OFC cables

- Joint closure multi-entry

- Straight/branch junction

- Waterproof

- Tiffin type ( Square box )

These are utilized for duct, aerial, and direct burial applications. They provide housing that is not only watertight but also fireproof and earthquake-resistant. After being spliced, they are adequately protected and are able to easily withstand impact, stress, and pulling. These are kept in enclosures so they may be served more quickly. Our products are delivered within the time frame that was agreed upon.

- Features

- Longer serving life

- Conveniently simple to use

- Delivery at the prescribed time

Fiber Optic Closure

Fiber optic closures protect and space spliced fiber optic lines. The fiber optic closure links store optical fibers outside or within. It can safeguard fiber junctions and cables because of its outstanding mechanical strength and sturdy outer shell, which prevents damage from a hostile environment. Protecting network connectivity matters regardless of network size, type, or configuration. According to different uses, customers can pick from several fiber optic closures to protect their networks.

- Horizontal Fiber Optic Closure

Horizontal fiber closure is flat or cylindrical. This fiber splice closure is most frequent in mounted aerials or underground. Horizontal fiber optic closures comprise one or more fiber splice trays to protect splices. Varied fiber optic splice closures use trays with different fiber counts and designs. Flat fiber splice closures have 12 or 24 fibers.

Waterproof and dustproof High-tensile construction plastic gives them adaptability and compression resistance. Fiber splice closures must be firmly secured to a pole or wire to avoid weather and wind damage.

- Vertical Fiber Optic Closure

Vertical fiber optic closure resembles a dome, hence it’s also called fiber dome closure. The Dome shape makes it easier to bury, but it can also be utilized above ground. Due to expanding network demands, there are several vertical fiber optic splice closure models and combinations. To fulfill the complicated needs of today’s fiber-optic networks, high-capacity versions and splicing tray variations are available. The number of inlet/outlet ports varies by application. Underground dome fiber optic splice closing requires high-level sealing and waterproofing. Underground closures must keep out insects and dirt. This vertical splice closure features five entries for 24 fiber optic splices in two 12-fiber trays.

Fiber Optic Splice Enclosure

Enclosures for fiber optic splices are used for the purpose of providing environmental protection for stripped fiber optic cable as well as fiber optic splices. This protection is provided by enclosures for fiber optic splices. These enclosures may be installed either indoors or outside according to the user’s preference. Enclosures for fiber optic cables that are put outside often have weatherproofing and watertight seals to protect the cables from the elements.

Within the typical wall-mounted splice enclosure, cable ties are utilized to provide support for the fiber optic cable. After that, the component of the cable’s strength that is being tested is safely linked to the support of the enclosure. It is absolutely necessary to ensure that the metallic strength members are safely grounded.

Under no circumstances whatsoever may individual optical fibers be left exposed outside of a splice tray. This is a strict prohibition. Depending on the type of fiber optic cable splice that is being utilized, splice trays typically hold either fusion or mechanical fiber optic cable splices.

Tips for Choosing a Fiber Optic Closure

The optical access portion has specific needs due to the network’s complexity. Fiber optic splice closures minimize difficulties. A durable optical closure can avoid repetitive network access link inspections. When the network reaches distributing and drop lines, a splice closure with extra connections will be useful. These variables will help you determine the right network splice closures.

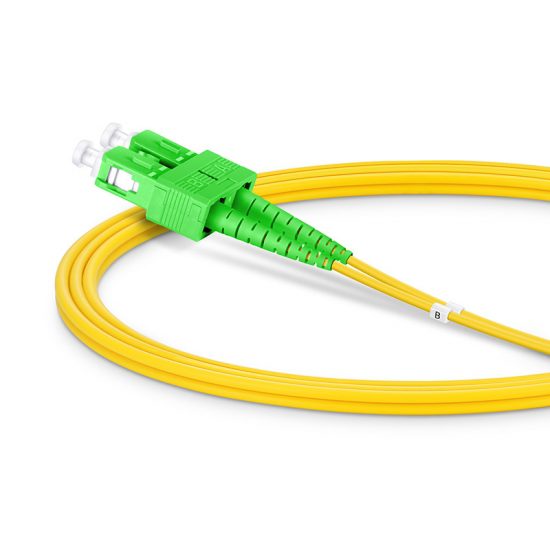

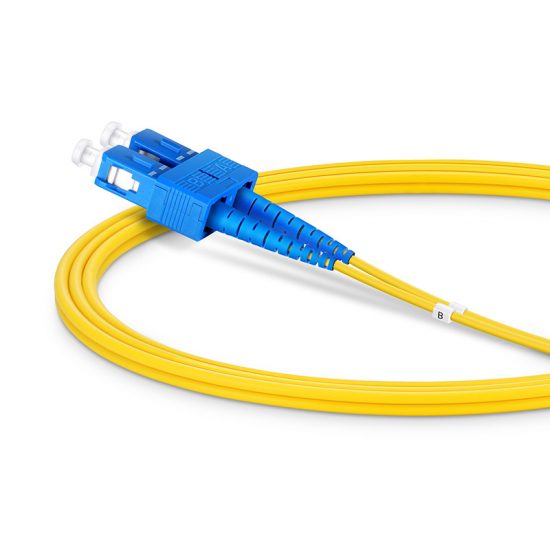

- Cable Compatibility

Good fiber optic closures accept any wire. Check cable compatibility before picking a closing. Fiber optic splice closure design depends on applications. Aerial and subsurface splice closures are different.

- Ports

The cable port’s capacity. Fiber optic closing ports indicate cable capacity. Cable termination ports are a splice closure’s cable entrance capacity. The number of ports in a closure depends on network capacity and cable count. To reduce the size of high-capacity closures, branch and drop cables have smaller ports.

- Splices

Unspliced cables won’t fit in fiber optic splice closure trays. Ribbon or mechanical splices diminish tray capacity. A well-designed splice can improve installation and performance. Consider splice types while choosing a splice closure.

- Grounding

Conductive network nodes must be joined and grounded for safe deployment and operation.

- Accessories

Fiber optic closures may hang from messenger wire, depending on network architecture. Pole-mounted. Both closures need accessories. Hardware should resist wear and environmental stresses.

- Minimize fiber cable bend radius

This may affect link performance. Consider cable management while selecting a fiber optic closure. Simple splice closures reduce handling damage.